ROVER 'P5/P5B'

Advertisments

1958 - 1973

| << Backwards | Germany, 1960 | Forwards >> | |

|---|---|---|---|

|

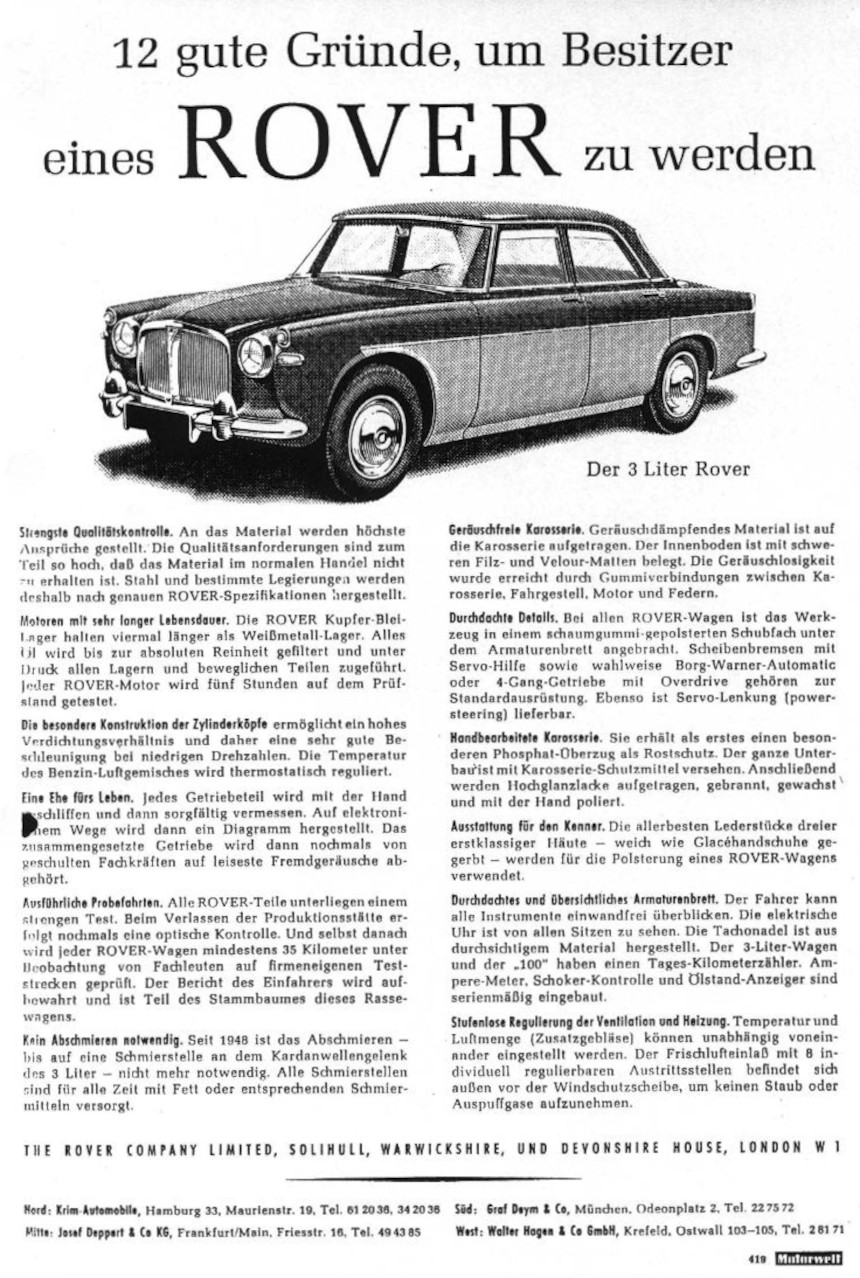

The text of this advertisment says: 12 good reasons to become a ROVER owner Strictest quality control. The highest demands are placed on the material. The quality requirements are sometimes so high that the material cannot be obtained in normal trade. Steel and certain alloys are therefore produced according to exact ROVER specifications. Engines with a very long service life. The ROVER copper-lead bearings last four times longer than white metal bearings. All oil is filtered to absolute purity and fed under pressure to all bearings and moving parts. Each ROVER engine is tested for five hours on the test bench. The special design of the cylinder heads allows a high compression ratio and therefore a very good acceleration at low rpm. The temperature of the fuel-air mixture is thermostatically controlled. A marriage for life. Every gear part is ground by hand and then carefully measured. A diagram is then produced electronically. The assembled gearbox is then checked again by trained specialists for the most powerful external noises. Extensive test drives. All ROVER parts are subjected to rigorous testing. When leaving the production plant, a visual check is carried out once again. And even after that, leather ROVER vehicles are tested for at least 35 kilometres under the supervision of experts on the company's own test tracks. The driver's report is kept and is part of the pedigree of this race car. No greasing necessary. Since 1948, greasing is no longer necessary - except for one grease point on the cardan shaft joint of the 3 litre. All lubrication points are supplied with grease or appropriate lubricants for all times. Noiseless bodywork. Noise-reducing material is applied to the bodywork. The interior floor is covered with heavy felt and velour mats. The noiselessness has been achieved by rubber connections between body, chassis, engine and springs. Well thought-out details. On all ROVER carriages the tools are stored in a foam rubber padded drawer under the dashboard. Disc brakes with servo-assist as well as optional Borg-Warner automatic or 4-speed transmission with overdrive are standard equipment. Power steering (power-steering) is also available. Hand-finished bodywork. It is the first to receive a special phosphate coating as rust protection. The entire substructure is coated with body protection agent. Then high-gloss lacquers are applied, fired, waxed and polished by hand. Equipment for the connoisseur. The very best pieces of leather from three first-class skins - tanned softly like glacé gloves - are used for the upholstery of a ROVER car. Well thought-out and clearly arranged dashboard. The driver has a perfect view of all instruments. The electric clock can be seen from all seats. The speedometer needle is made of transparent material. The 3 litre car and the "100" have a trip meter. Ampere-meter, choker control and oil level indicator are fitted as standard. Continuous control of ventilation and heating. Temperature and air volume (additional fan) can be adjusted independently. The fresh air intake with 8 individually adjustable outlets is located outside in front of the windscreen to prevent dust or exhaust fumes from entering the vehicle. The advert names four importers | ||

| << Backwards | This advertisment appeared in several issues of the 'ADAC Motorwelt' | Forwards >> | |

© 2021-2026 by ROVER - Passion / Michael-Peter Börsig

Deutsch

Deutsch